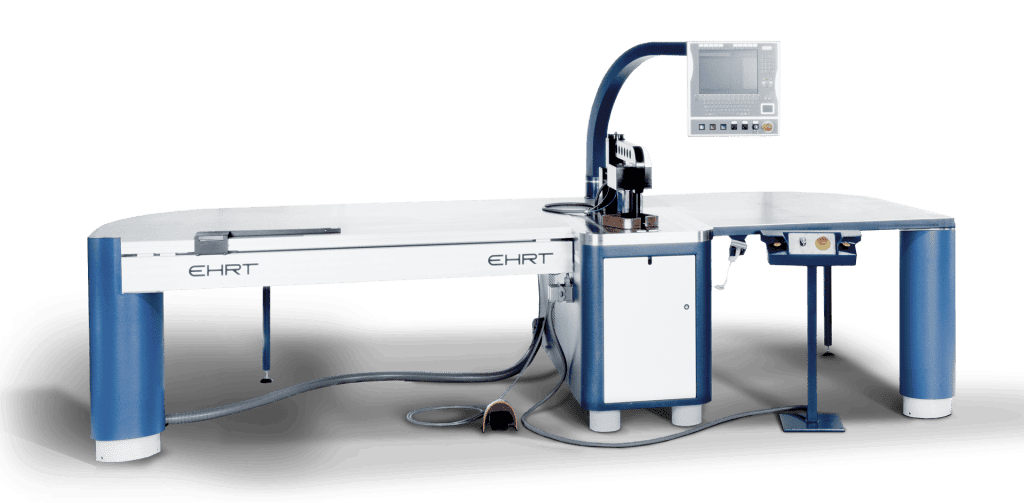

EHRT EB 40 Professional E Bending Machine

Features:

- Powered by an Electrical servo-drive.

- Large tables for bigger work-pieces.

- Capable for a 3-shift operation set up.

- Quick tool change – no extra tools needed for changing the EHRT bending tools.

The EB40 Professional E is distinguished by an even more robust but compact design than the Standard series machines.

All kinds of bending types can be set up with EHRT bending machines. Offset bending, flat bending, bending on edge, torsion bending, closed shapes and U-bends are some examples. The machines offer outstanding bending accuracy of +/- 0.1°. With the EB40 Professional E, side lengths up to 2000mm can be bent without any problems. The tool change on the machines is carried out via a user-friendly plug-in system. This guarantees very quick and easy setup times with powerful and precise bending tools.

Save energy with electric drive

The “E” in the name stands for the electric drive of the machine, up to 70 % energy efficiency can be achieved. Because there is no hydraulic unit, the machine is significantly quieter and requires little maintenance. The CNC-controlled side stop is included as standard. The machine’s larger tables allow the operator greater degrees of flexibility in the bending process, especially with more complex work-pieces. Furthermore, the machine is also suitable for use in companies operating a 3 shift system.

The PLC machine controller from Beckhoff enables machine maintenance and software updates via remote access.

In combination with the EHRT bending tools, the bending machines offer an extremely high degree of repeatability so that each part is bent identically. In combination with the software solutions, this results in simple but precise machine handling.

PowerCut & PowerBend are the standard software solutions included with the machines, for the bending machines PowerBend and for the punching machines Powercut. It is used to create programs and controlling the machine. It is simple and intuitive and allows for simple operation and control of the machines, even for more complex work-pieces. As the pieces are created the touchscreen display shows the piece along with position of any holes cutouts and bends. The software supports DXF and Eplan imports.

Also there is an office version allowing parts production in the office, if used with Network licence the bending, punching and office computer use a common database, assuring that all machines can work with the same information. The office software if enabled with PowerCut & PowerBend software can create the complete finished part with holes bends and the correct developed length required. In turn the punching machine picks up the program from the database and creates the flat piece, then passes it to the bending machine. Who in turn picks up the same program from the database and creates the bends, job completed.