EHRT FlexPunch Compact Punching Machine

Features:

- 4 Tool Stations – When using the 3 station Multi-Tool the machine can be fitted with up to 9 punches and a cropping punch.

- Thread Forming Station – Use of 1 SingleTap station possible

- Modular Machine System – Each machine can be adopted to the clients individual requirements, even later on.

- Intuitive Handling of Software – The punching machines can be optimally linked with the bending machines so that production can be carried out based on a single production file from a common database.

- Different Marking Systems and Feasible – Inkjet printer, label printer, needle embosser

- Several ejector positions can be set up on the sorting belt

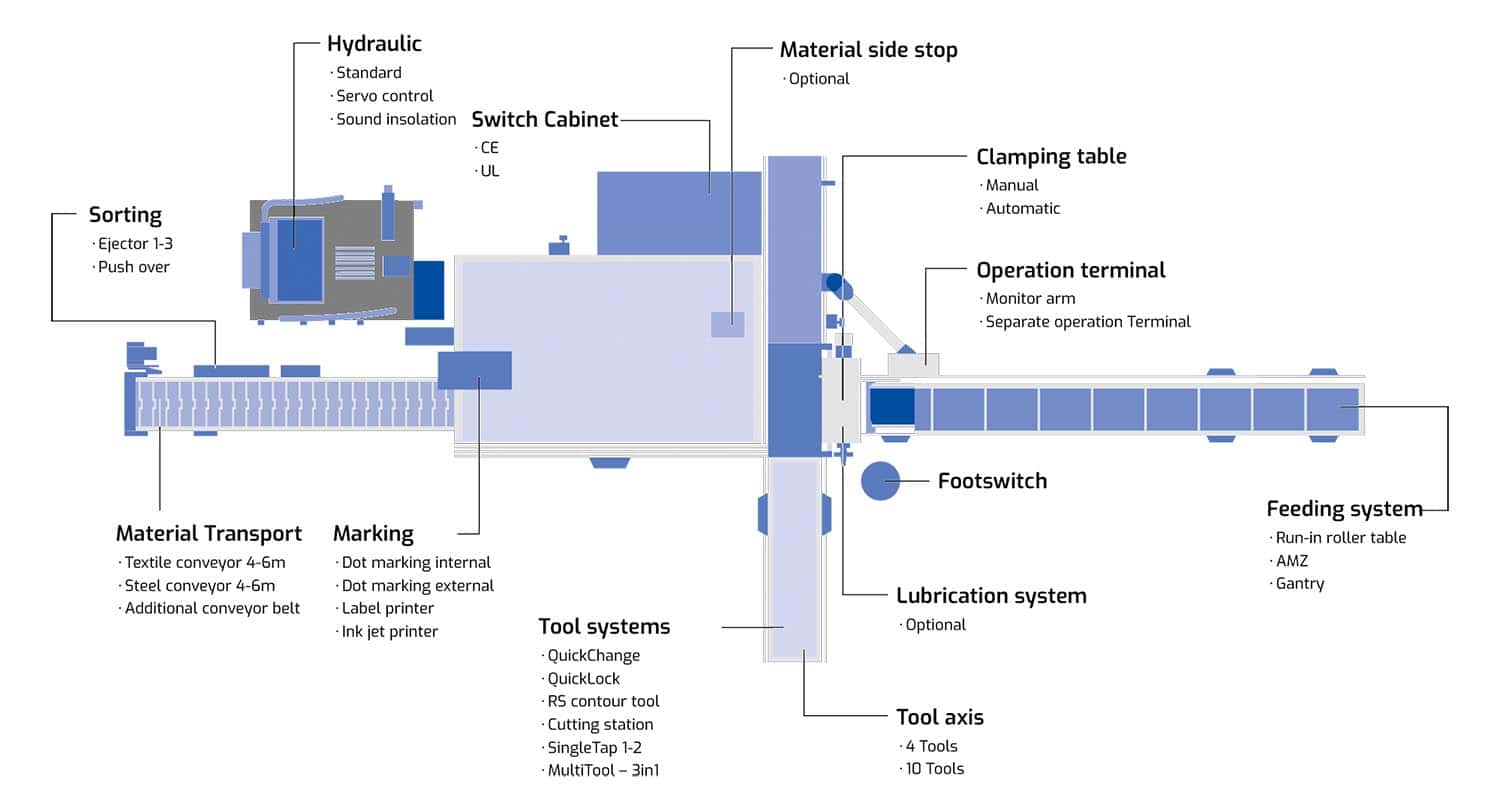

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the client’s individual requirements via individual components. The FlexPunch compact is the smaller version of the two and is particularly suited to production sites with limited space.

The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with amazing accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can also be automated as much as possible with more options. This makes the punching machines extremely costeffective.

Software solutions from EHRT enable a customised and smooth production flow of punching machines. In addition, the punching machines can be optimally linked with the bending machines so that production can be carried out based on a single production file from a common database.

The PLC machine controller from Beckhoff enables machine maintenance and software updates via remote access.

Compact and modular

EHRT’s tool system allows simple and fast tool changes, minimising setup times. When using MultiTools 3in1, the machine can be fitted with up to 9 punches and a cutting tool. Furthermore, it is possible to install 1-2 thread forming stations. There are several sorting belt options that can also be equipped with a variety of ejector positions. The machine is equipped with a hydraulic cylinder with a force of 340 kN. With the FlexPunch series machines, it is possible to punch material that is 15-200 mm (0.6-7.9“) wide and 3-16 mm (0.1-0.6“) thick.

During processing, the workpieces are clamped laterally by a special clamp in order to minimise any damage to the workpiece caused by the shape of the clamp. Furthermore, thanks to the special clamp, punching can be carried out over the entire workpiece.

The tools are fitted with particularly strong springs which provide high retraction forces. Thus you can operate with small cutting clearances even in thick metal bars.

Afterwards or during production, it is possible to label the workpieces with different systems. This can be used for additional production steps or also for your clients’ specifications.

More Options

- Aluminium lubrication

- Thread formers

- Punching of profiles

- PunchPRO Nesting Software

- Automatic Loading System

- Gantry Automatic Storage

- Workpiece marking

FlexPunch Series